Over the last few months, I have been receiving more infrastructure related inquiries. Most of these inquires are in reference to power infrastructures. Electrical engineering has always been one of my engineering disciplines. Over the weekends, I have been putting together these notes, pictures, diagrams, calculations and videos to help explain electrical fundamentals, generator function, power production, power distribution and large scale power consumption.

Part A - Electrical Fundamentals and Key Terms

Part B - Quick Overview of Generator Function - Making Electricity

Part C - Power Production Examples

Part D - Power Distribution (Grid and Data Center) Diagrams

Part E - Large Scale Power Consumption Examples

Part A - Electrical Fundamentals and Key Terms

Key Term - Electric Current

The movement of electric charge is known as an electric current, the intensity of which is usually measured in Amperes. Current can consist of any moving charged particles; most commonly these are electrons, but any charge in motion constitutes a current.

Key Term - Ampere (Amp)

In practical terms, the ampere is a measure of the amount of electric charge passing a point in an electric circuit per unit time with 6.241 × 1018 electrons, or one coulomb per second constituting one ampere.

Ampère's force law states that there is an attractive or repulsive force between two parallel wires carrying an electric current. This force is used in the formal definition of the Ampere, which states that it is "the constant current that will produce an attractive force of 2 × 10–7 newton per meter of length between two straight, parallel conductors of infinite length and negligible circular cross section placed one meter apart in a vacuum". The SI unit of charge, the coulomb, "is the quantity of electricity carried in 1 second by a current of 1 Ampere". Conversely, a current of one ampere is one coulomb of charge going past a given point per second.

Key Term - Volt

A single volt is defined as the difference in electric potential across a wire when an electric current of one ampere dissipates one watt of power.

Key Term - Watt

One watt is the rate at which work is done when an object's velocity is held constant at one meter per second against constant opposing force of one newton.

Key Term - Kilowatt

The kilowatt is equal to one thousand watts, or one sthene-metre per second. This unit is typically used to express the output power of engines and the power consumption of electric motors, tools, machines, and heaters. It is also a common unit used to express the electromagnetic power output of broadcast radio and television transmitters.

One kilowatt of power is approximately equal to 1.34 horsepower. A surface area of one square meter on Earth receives typically one kilowatt of power of sunlight from the sun (on a clear day at mid day).

Key Term - Kilowatt-Hour - It is a unit of work or energy equal to that done by one kilowatt of power acting for one hour. A Kilowatt is 1,000 watts or 1.34 Horsepower. (1 KW = 1.34 Horsepower) / 1 Megawatt = 1,000 Kilowatts or 1,340 Horsepower (1 MW = 1,341 Horsepower)

Key Term - Megawatt

The megawatt is equal to one million watts. Many events or machines produce or sustain the conversion of energy on this scale, including lightning strikes; large electric motors; large warships such as aircraft carriers, cruisers, and submarines; large server farms or data centers; and some scientific research equipment, such as supercolliders, and also in the output pulses of very large lasers. A large residential or commercial building may consume several megawatts in electric power and heat.

The productive capacity of electrical generators operated by a utility company is often measured in megawatts. A typical wind turbine (or wind energy converter) has a power capacity of 1 to 3 MW. On railways, modern high-powered electric locomotives typically have a peak power output of 5 or 6 MW, although some produce much more. The Eurostar, for example, consumes more than 12 MW, while heavy diesel-electric locomotives typically produce/consume 3 to 5 MW.

Watt Examples

- A person having a mass of 100 kilograms who climbs a 3 meter high ladder in 5 seconds is doing work at a rate of about 600 watts. Mass times acceleration due to gravity times height divided by the time it takes to lift the object to the given height gives the rate of doing work or power.

- A laborer over the course of an 8-hour day can sustain an average output of about 75 watts; higher power levels can be achieved for short intervals and by athletes.

- A medium-sized passenger automobile engine is rated at 50 to 150 kilowatts – while cruising it will typically yield half that amount.

- A typical household incandescent light bulb has a power rating of 25 to 100 watts; fluorescent lamps typically consume 5 to 30 watts to produce a similar amount of light.

- A typical coal power plant produces an output of 600–700 megawatts.

- A typical nuclear power plant produces an output of 900–1300 megawatts.

Key Term - Confusion of Watts, Watt-Hours, and Watts per Hour

The terms power and energy are frequently confused. Power is the rate at which energy is generated or consumed.

For example, when a light bulb with a power rating of 100W is turned on for one hour, the energy used is 100 watt-hours (W•h), 0.1 kilowatt-hour, or 360 kJ. This same amount of energy would light a 40-watt bulb for 2.5 hours, or a 50-watt bulb for 2 hours. A power station would be rated in multiples of watts, but its annual energy sales would be in multiples of watt-hours. A kilowatt-hour is the amount of energy equivalent to a steady power of 1 kilowatt running for 1 hour, or 3.6 MJ (1000 watts x 3600 seconds (i.e., 60 seconds/minute x 60 minutes/hour) = 3600000 Joules = 3.6 MJ).

Terms such as watts per hour are often misused. Watts per hour properly refers to the change of power per hour. Watts per hour (W/h) might be useful to characterize the ramp-up behavior of power plants. For example, a power plant that reaches a power output of 1 MW from 0 MW in 15 minutes has a ramp-up rate of 4 MW/h. Hydroelectric power plants have a very high ramp-up rate, which makes them particularly useful in peak load and emergency situations.

Major energy production or consumption is often expressed as terawatt-hours for a given period that is often a calendar year or financial year. One terawatt-hour is equal to a sustained power of approximately 114 megawatts for a period of one year.

The watt second is a unit of energy, equal to the joule. One kilowatt-hour is 3,600,000 watt-seconds. The watt-second is used, for example, to rate the energy storage of flash lamps used in photography, although the term joule is normally used rather than watt-second.

Part B - Quick Overview of Generator Function - Making Electricity

Generator operation is based on the principle of electromagnetic induction. This means that voltage is generated when any conductor is moved at right angles through a magnetic field. When voltage is produced in this manner, it will cause the current to flow in the conductor if that conductor is a complete circuit.

Key Terms (Below) - For Reference

Armature - An armature starts out as a bare hardened steel shaft. To this shaft is added a series or group of non-insulated copper wires wound close together. They in turn will form what is called a loop. The loops of wire are then embedded in a series of slots in an iron core. This iron core is then attached to the armature shaft. This shaft spins and helps to generate the electrical current. As you might guess, the size of the wire and the number of wires in the loop will affect the output of the generator.

Commutator - The commutator is a series of segments or bars that are also attached to the armature shaft at the rear of the armature. It is the wire ends from the loops of the armature windings in the iron core that are attached to the commutator. When this is done, a complete circuit is formed.

Field Coils - Field coils are the windings or the group of wires that are wrapped around the pole magnet. It is the job of the field coils to take the current drawn to the pole magnet, and make it stronger. (Field coils are the windings that are attached to the inside of the generator housing.) This increased strength in current will force even more current to be drawn to the pole magnets, which will continue to build up current. This is how the current produced by the generator is built up and increased, until it can be used.

Brushes - After the generator develops the current, it is the brushes that carry the current to the “field” circuit and the “load” circuit, so the electricity can be used by the battery and the accessories. This process is called “commutation.” The brushes will ride on the commutator segments of the armature. Brush holders hold the brushes in position by way of spring tension.

Most automotive generators will contain two brushes, one that is grounded to the frame of the generator and one that will be insulated from the frame. The insulated brush is the positive brush and is connected to the “A” terminal of the generator, and to one end of the field coils. The other end of the field coil is connected to the insulated “F” terminal of the generator.

Bearing and Bushes - At either end of a generator you will find a bushing or a bearing. They have the job of making the armature shaft run true in the housing between the field coils and pole shoes. Bushings will be made of copper or brass and are soaked in oil before they are installed. The brass or copper bushing material is porous and able to absorb the oil like a sponge. This provides the lubrication between the shaft and the bushing. They can also be re-oiled from the oiling tube on the outside of the generator.

Part C - Power Production Examples

-Combustion Turbine - Between 261 MW (Simple Cycle) and 791 MW (Combined Cycle)

-Hydroelectric Turbine Dam - Between 500 MW and 1300 MW (Configuration Example: 4 x 350 MW Turbines) = 1400 MW - Hoover Dam is at 2,080 MW (2,789,326 Horsepower) coming from 17 Turbines (9 in Arizona Wing and 8 in the Nevada Wing). Hoover Dam generates, on average, about 4 billion kilowatt-hours of hydroelectric power each year for use in Nevada, Arizona, and California - enough to serve 1.3 million people.

- Nuclear Reactor Turbine - Boiling Water Type - Between 500 MW and 1,300 MW

- Nuclear Reactor Turbine - Pressurized Water Type - Between 500 MW and 1,300 MW (Arizona Palo Verde Plant has three reactors with the largest combined generating capacity of about 3,937 MW)

- Coal Fired Turbine - Between 500 MW and 1300 MW

- Wind Turbine - Between 1.5 MW and 4.1 MW (Each Wind Turbine)

Note: A 1 MW generator produces 1000 KWH every hour assuming its fully loaded. There are 8,760 hours in a year, so assuming no downtime, it would generate 8,760,000 KWH in a year.

1MW = 1000000 Watts

1 KW = 1000 Watts

1 MW = 1000 KW

1 MW for 1 hour = 1 MWH

1 MWH = 1000 KWH

Note: On average, the largest medium speed engines in current production have outputs up to approximately 20 MW (27,000 Horsepower)

Coal Fired Plant Turbine

Coal-fired units produce electricity by burning coal in a boiler to heat water to produce steam. The steam, at tremendous pressure, flows into a turbine, which spins a generator to produce electricity. The steam is cooled, condensed back into water, and returned to the boiler to start the process over.

Calculation: A US Coal Plant Average Size of 667 MW (4,914 Tons of Coal per Day / 120 Tons of Coal per Rail Car = 41 Rail Cars of Coal) - 667 MW Power

Roughly 333,500 Households serviced through a 667 MW Power Plant.

Video - Coal Fired Plant Animation Video - https://www.youtube.com/watch?v=FnwN3wtRMbk

Fossil G Series 500MW-1100MW

Fossil G series steam turbines are suitable for 500MW-1100MW power plants and feature versatile 3-casing or 4-casing configurations with two double-flow exhaust LP turbine sections. These turbines are ideal for subcritical, supercritical and ultra-supercritical steam conditions in both 50Hz and 60Hz.

Coal Fired Plant Turbine

Combustion Turbine

The turbine burns either natural gas or oil. Fuel is mixed with compressed air in the combustion chamber and burned. High-pressure combustion gases spin the turbine, which drives the generator.

Video - Combustion Turbine (Combined Cycle) Animation - https://www.youtube.com/watch?v=_7-WtOmf8kA

Video - Siemens SGT-750 Gas Turbine Flythrough - https://www.youtube.com/watch?v=eWOqXPCdBMI

Video - GE FlexAero LM6000-PH Aeroderivative Gas Turbine - https://www.youtube.com/watch?v=FIa8I6FE5V4

9E Heavy Duty Gas Turbine

Output (MW): 127.6 Simple Cycle, 391 Combined Cycle

The 9E gas turbine accommodates a wide range of fuels including natural gas, light and heavy distillate oil, naphtha, crude, residual oil, blast furnace gas (BFG), syngas, and biofuels.

Note: Simple Cycle involves peaking duty or mid/base load operation. The 9E gas turbine provides fast start capability for peaking duty. For power generation, the 9E gas turbine provides 127.6 MW of reliable power.

Note: Combined Cycle is when the gas turbine generator produces electricity and captures the waste heat to make steam to generate additional electricity via a steam turbine.

Combustion Turbine

Nuclear Reactor - Boiling Water Type

Water is heated through the controlled splitting of uranium atoms in the reactor core and turns to steam. Pumps force the water through the reactor at top speed, maximizing steam production. Steam drives the turbines that turn the generator that makes electricity. Cooling water from the river condenses the steam back into water. The river water is either discharged directly back to the river or cooled in the cooling towers and reused in the plant.

US Nuclear Plant Average Size of 846 MW

- 8 pellets needed to power a average home for a year.

- Pellets sealed into metal tubes.

Pellet tubes welded together to form fuel bundle.

- Several thousand fuel bundles are inserted into a large tank called a Calandria

- Heavy Water is used as Moderator - Heavy water is 10% heavier than normal water and contains higher than normal amounts of Deuterium which is a form of Hydrogen.

Note: 1 Kilogram (2.205 Pounds) of Uranium-235 has the capacity to produce as much energy as 1,360,777 kilograms (1,500 tons) of coal. (Uranium-235 keeps producing average power output for over 2 years at average decay rate)

Note: 3.276 Kilograms (7.222 Pounds) of Uranium-235 has the capacity to produce as much energy as 4,457,905 kilograms (4,914 tons) of coal. (Uranium-235 keeps producing average power output for over 2 years at average decay rate)

Video - Nuclear Reactor - Boiling Water Type Animation - https://www.youtube.com/watch?v=TPUk5U2zf1U

Nuclear Reactor - Pressurized Water Type

Water is heated through the splitting of uranium atoms in the reactor core. The water, held under high pressure to keep it from boiling, produces steam by transferring heat to a secondary source of water. The steam is used to generate electricity. Cooling water from the river condenses the steam back into water. The river water is either discharged directly back to the river or cooled in the towers and reused in the plant.

Video - Nuclear Reactor - Pressurized Water Type Animation - https://www.youtube.com/watch?v=-WPyKmsK5hs

Nuclear Reactor Turbine

GE's nuclear N series steam turbines are two-stage, reheat, tandem compound designs for nuclear applications up to 1,500 MW. The steam turbines feature monoblock LP rotors, delivering high reliability and low cost of maintenance.

Hydroelectric Dam Turbine

Water from the reservoir rushes through the penstock into the powerhouse. The water spins the turbine, which drives the generator. Inside the generator is a large electromagnet that spins within a coil of wire, producing electricity.

Video - Hydroelectric Dam Animation - https://www.youtube.com/watch?v=KJwxg0AQTbU

Hydroelectric Dam Turbine Diagram

Wind Turbine

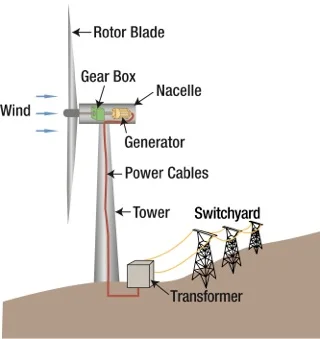

A turbine and gear box are mounted in a casing called a nacelle, and rotor blades are attached to the turbine. The turbine localizes the energy of the turning rotor blades in a single rotating shaft that generates electricity.

Wind Turbine Diagram

The 4.1-113 Wind Turbine is designed specifically for the offshore environment, with reliability and availability as the primary drivers. This machine includes direct-drive technology, built-in redundancy in the generator and converter, and in-situ repair capabilities.

Wind Turbine

Pumped Storage Plant

During periods of low power demand, the pump-turbine pumps water up into the mountaintop reservoir. During periods of high demand water from the reservoir flows down through the mountain to the power plant, generating electricity.

Pumped Storage Plant Diagram

Solar Photovoltaic System

Photovoltaic (PV) systems use semiconductor cells that convert sunlight directly into electricity. Direct current from the PV cells, which are arrayed in flat panels, flow into inverters that change it to alternating current.

Solar Photovoltaic System Diagram

Methane Gas Facility

Pipes collect methane gas produced by decaying waste, and the gas is burned to generate electricity.

Methane Gas Facility Diagram

Part D - Power Distribution (Grid and Data Center) Diagrams

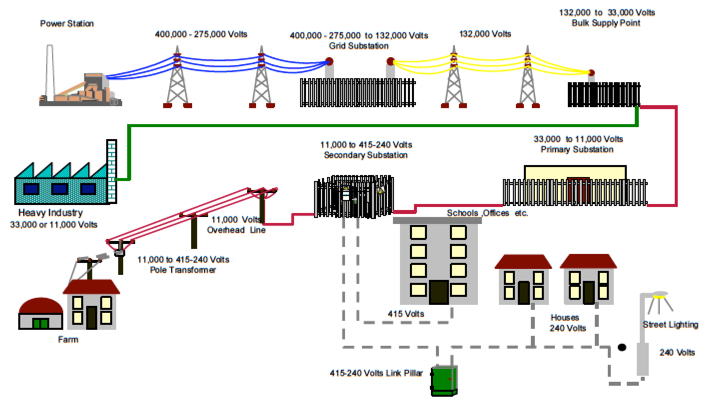

Electricity Grid Schematic

Power Distribution Network (Based on 240 Home Voltage - EMEA Example)

Data Center Critical Power Delivery Chain

Part E - Large Scale Power Consumption Examples

D1 - Power Usage Baseline for Examples (Cisco Allen Data Center)

Data Center Power Usage: 5 MW (Coming from Two 2.25 MW Electrical Power Feeds)

Two 8.4 MW Generators (11,264 Horsepower Each / 22,529 Horsepower Total)

Up to 18.5 kW/rack, 6.5 kW (Average)

Note: There are 1,000 kW in 1 MW (1,341 HP)

D2 - Cruse Ship Example - 75.6 MW - Equates to 15 Cisco Allen Data Centers Power Usage

Royal Caribbean Mariner of the Seas (Similar Specifications to Carnival Dream Cruise Ship) is producing (Diesel-Electric Power Generation) 75,600 kW at 2,871 Gallons an hour of Diesel fuel. This ship consumes 35,000 gallons of Diesel fuel per day. The Royal Caribbean Mariner of the Seas trips are a 3, 4, 5, 7, 15 and 16 day durations. A 16 day trip consumes 560,000 Gallons of Diesel / 4299 (Total Passenger and Crew Count) / 16 Days = 8.14 Gallons of diesel fuel per person per day. This form of mass transportation proves to be very efficient.

Total Trip Fuel Consumed (For All Systems - Main Propulsion and All On-Board Facilities)

3 Days: 105,000 Gallons of Diesel

4 Days: 140,000 Gallons of Diesel

5 Days: 175,000 Gallons of Diesel

7 Days: 245,000 Gallons of Diesel

15 Days: 525,000 Gallons of Diesel

16 Days: 560,000 Gallons of Diesel

Royal Caribbean Mariner of the Seas has diesel-electric machinery, consisting of six Wärtsilä 12V46 diesel engines, with a total power of 75,600 kW. This is the same power plant configuration as the Carnival Dream Cruise Ship.

Power Generation Details

Class & Type: Voyager Class Cruise Ship

Tonnage: 138,00 GT

Length: x m (1,020 ft)

Beam: x m (157.50 ft)

Draft: 29 ft (8.8 m)

Decks: 15

Installed power: 6 × Wärtsilä 12V46 Diesel Engines (12,600 kW Each)

Total Power Generation: 75,600 kW

Propulsion: Diesel-Electric

Two ABB Azipods, one Fixipod and Four Bow Thrusters

Speed: 22 knots (41 km/h; 25 mph) (Service)

24 knots (44 km/h; 28 mph) (Max)

Capacity: 3,114 Passengers

Crew: 1,185

Fuel Consumption at Full Speed: 10,637 kg/h (2,871 gal/h)

Wärtsilä 12V46 Diesel Engine

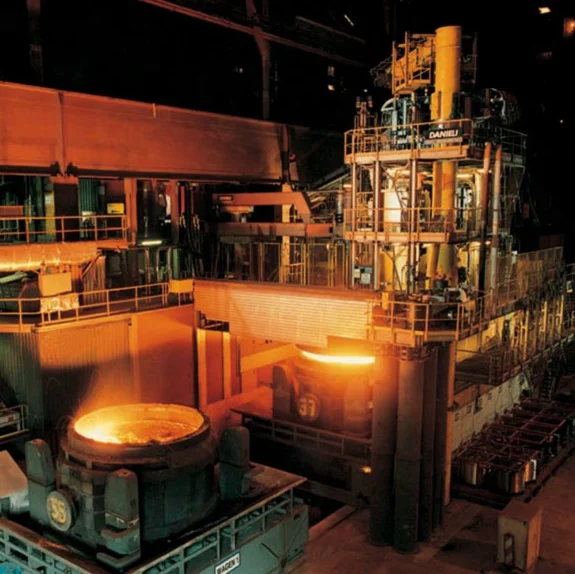

D3 - Medium Electric Arc Furnace (EAF) for Steel Production - 175 MW - Equates to 35 Cisco Allen Data Centers Power Usage

In the Electric Arc Furnace (EAF), recycled steel scrap is melted and converted into high quality steel by using high-power electric arcs. The main task of most modern EAFs is to convert the solid raw materials to liquid crude steel as fast as possible and then refine further in subsequent secondary steelmaking processes.

Small Electric Arc Furnace (EAF) - To 80 MVA

Medium Electric Arc Furnace (EAF) - To 140 MVA

Large Electric Arc Furnace (EAF) - To 320+ MVA

8x 32MVA Transformers/Rectifiers for 256 MVA total power (175 MW developed at the arc)

Medium sized Electric Arc Furnaces begin at 80 MVA and large at 140 MVA. The largest AC furnace in Turkey draws 250 MVA and Tokyo Steel has a Danieli-built continuous-charge 320 MVA DC furnace. It has 2 top electrodes, 4 bottom electrodes (2 per 'phase') and six transformers.

Video - Siemens Electric Arc Furnace Quantum - https://www.youtube.com/watch?v=m2bMpDsV5y0

Video - Electric Arc Furnace - Furnace Operation - https://www.youtube.com/watch?v=jtbEf0eC9cc

Video - Electric Arc Furnace - Close Up During Electric Arch - https://www.youtube.com/watch?v=YNEn26vfIpc

Basic Layout of Electric Arc Furnace Diagram