For one of my UC Berkeley projects, I wanted to demonstrate complex rapid prototyping through Additive Manufacturing. Since I was young, I have loved Jet Engines and thought this would be the perfect project.

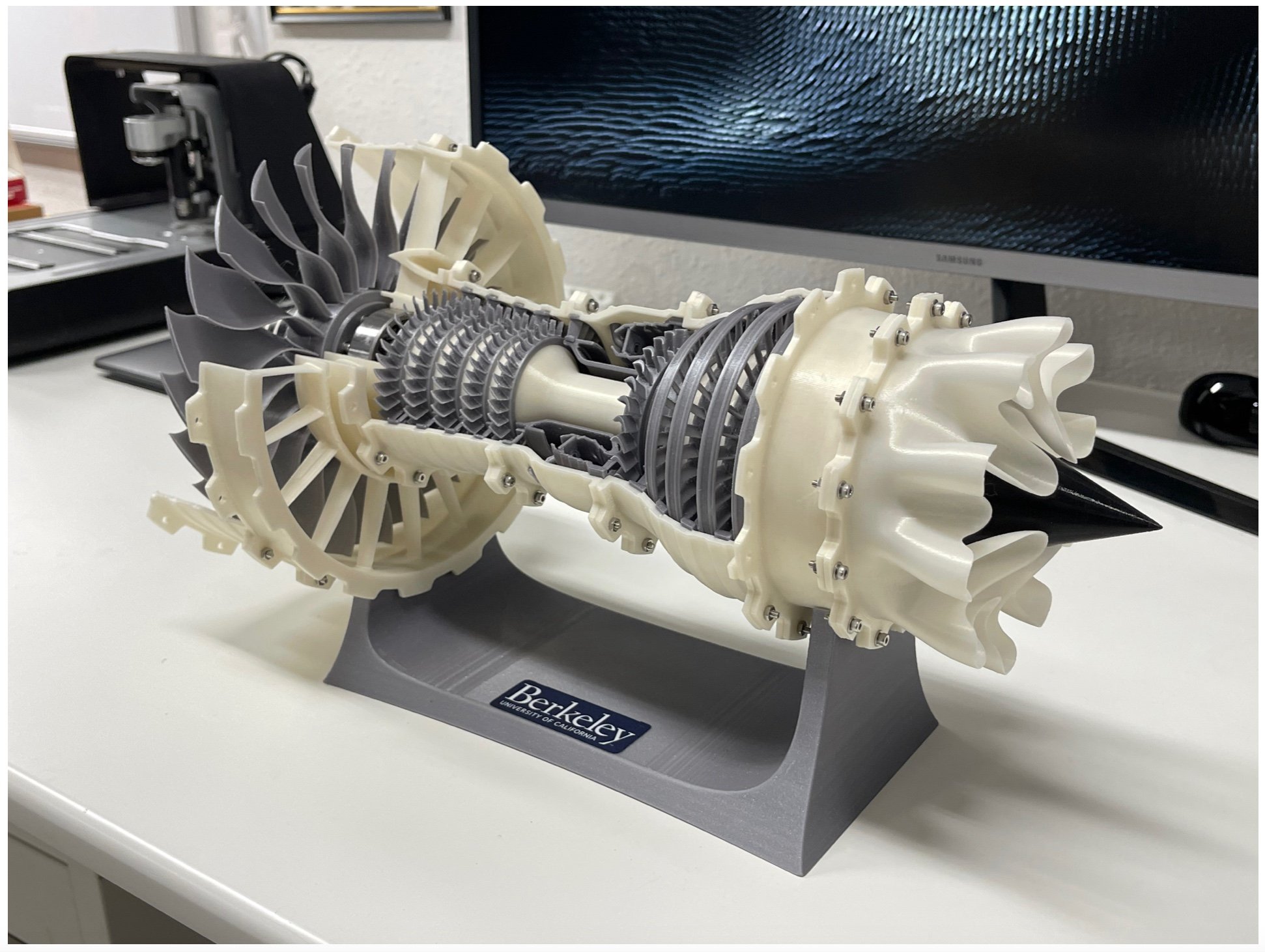

My 3D Printed Jet Engine project for UC Berkeley was a great way to demonstrate the power of rapid prototyping through Additive Manufacturing. I chose to focus on a Jet Engine because of the complexity and beauty of the design. Using 3D Printing, I created a working model with smooth curves and intricate details.

The process of constructing the Jet Engine started by breaking down the components into smaller pieces and determining which parts needed to be printed. Once all the parts were fabricated, they needed to be assembled into one cohesive unit - this is where 3D Printing came in handy again. Using FFF/FDM 3D Printing, I could quickly and accurately assemble the parts into a functional turbine engine. Utilizing 3D Printing for assembly allowed for quick iterations when making adjustments. Heavy-duty bearings utilized in the build permitted for fully functional and independent rotations.

Fascinated by this potential, I am creating more complex designs and exploring other applications, such as aerodynamic testing with 3D Printed turbines in wind tunnels and more accurate simulations through multi-physics software tools. I hope to continue pushing the boundaries of 3D Printing and its potential applications in the engineering world.

Operating Principles Behind the Jet Engine

A Jet Engine works by using a fan to draw in air and compress it. The compressed air is then passed through a combustor, where fuel is injected and burned, creating the heat necessary for thrust. This heated air is then forced through one or more turbines that take some of the energy from the hot gas stream and convert it into mechanical power, which powers the fan. Finally, the remaining hot gas stream is expelled from the nozzle to provide thrust for aircraft propulsion.

The entire process can be broken down into four simple steps: Induction, Compression, Combustion, and Expansion (Thrust). By understanding how these four processes work together to create motion, engineers can build powerful yet efficient engines. With 3D Printing, engineers are now able to develop Jet Engines that are even more efficient and powerful. By creating intricate components with smooth curves and precise measurements, 3D Printed Jet Engines can take full advantage of fluid dynamics and provide better overall performance.