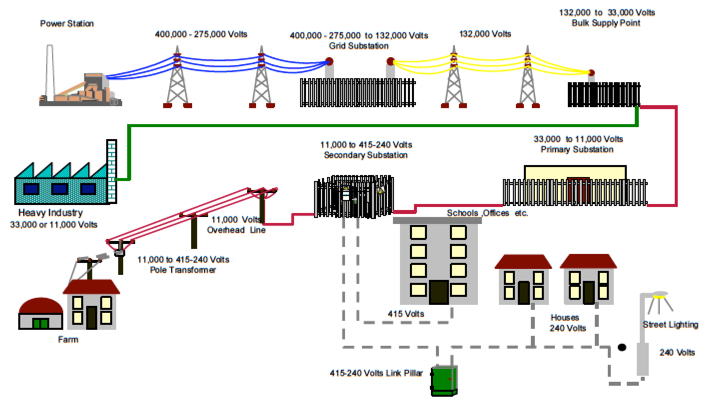

Over the last few months, I have been receiving more infrastructure related inquiries. Most of these inquires are in reference to power infrastructures. Electrical engineering has always been one of my engineering disciplines. Over the weekends, I have been putting together these notes, pictures, diagrams, calculations and videos to help explain electrical fundamentals, generator function, power production, power distribution and large scale power consumption.

Part A - Electrical Fundamentals and Key Terms

Part B - Quick Overview of Generator Function - Making Electricity

Part C - Power Production Examples

Part D - Power Distribution (Grid and Data Center) Diagrams

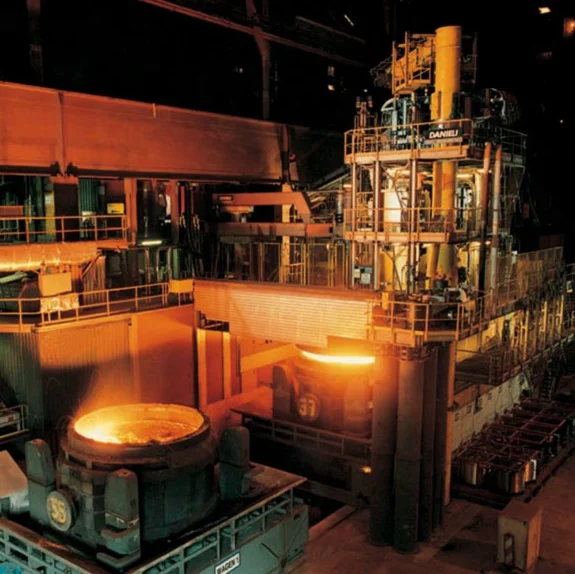

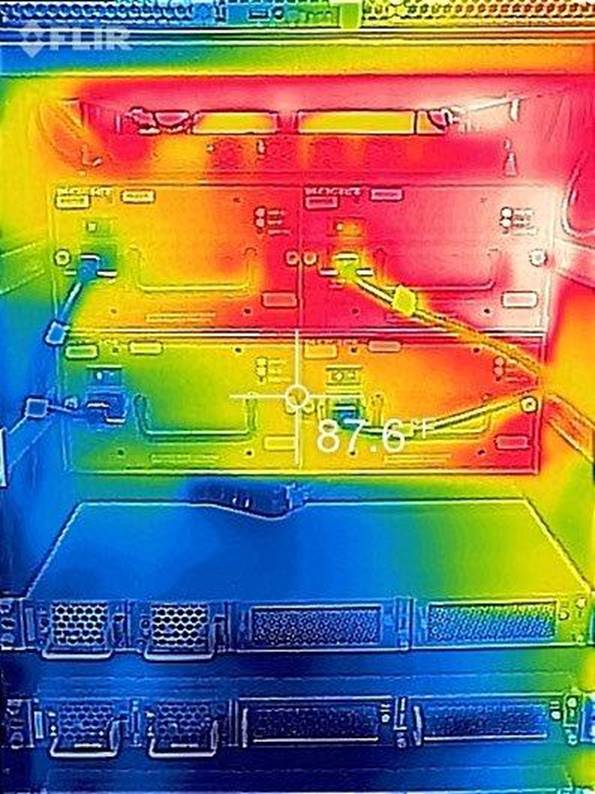

Part E - Large Scale Power Consumption Examples

Part A - Electrical Fundamentals and Key Terms

Key Term - Electric Current

The movement of electric charge is known as an electric current, the intensity of which is usually measured in Amperes. Current can consist of any moving charged particles; most commonly these are electrons, but any charge in motion constitutes a current.

Key Term - Ampere (Amp)

In practical terms, the ampere is a measure of the amount of electric charge passing a point in an electric circuit per unit time with 6.241 × 1018 electrons, or one coulomb per second constituting one ampere.

Ampère's force law states that there is an attractive or repulsive force between two parallel wires carrying an electric current. This force is used in the formal definition of the Ampere, which states that it is "the constant current that will produce an attractive force of 2 × 10–7 newton per meter of length between two straight, parallel conductors of infinite length and negligible circular cross section placed one meter apart in a vacuum". The SI unit of charge, the coulomb, "is the quantity of electricity carried in 1 second by a current of 1 Ampere". Conversely, a current of one ampere is one coulomb of charge going past a given point per second.

Key Term - Volt

A single volt is defined as the difference in electric potential across a wire when an electric current of one ampere dissipates one watt of power.

Key Term - Watt

One watt is the rate at which work is done when an object's velocity is held constant at one meter per second against constant opposing force of one newton.

Key Term - Kilowatt

The kilowatt is equal to one thousand watts, or one sthene-metre per second. This unit is typically used to express the output power of engines and the power consumption of electric motors, tools, machines, and heaters. It is also a common unit used to express the electromagnetic power output of broadcast radio and television transmitters.

One kilowatt of power is approximately equal to 1.34 horsepower. A surface area of one square meter on Earth receives typically one kilowatt of power of sunlight from the sun (on a clear day at mid day).

Key Term - Kilowatt-Hour - It is a unit of work or energy equal to that done by one kilowatt of power acting for one hour. A Kilowatt is 1,000 watts or 1.34 Horsepower. (1 KW = 1.34 Horsepower) / 1 Megawatt = 1,000 Kilowatts or 1,340 Horsepower (1 MW = 1,341 Horsepower)

Key Term - Megawatt

The megawatt is equal to one million watts. Many events or machines produce or sustain the conversion of energy on this scale, including lightning strikes; large electric motors; large warships such as aircraft carriers, cruisers, and submarines; large server farms or data centers; and some scientific research equipment, such as supercolliders, and also in the output pulses of very large lasers. A large residential or commercial building may consume several megawatts in electric power and heat.

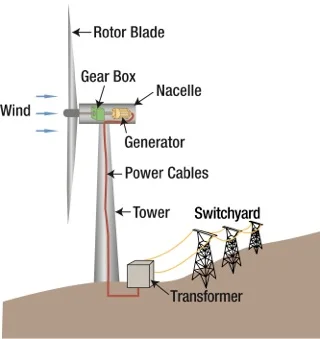

The productive capacity of electrical generators operated by a utility company is often measured in megawatts. A typical wind turbine (or wind energy converter) has a power capacity of 1 to 3 MW. On railways, modern high-powered electric locomotives typically have a peak power output of 5 or 6 MW, although some produce much more. The Eurostar, for example, consumes more than 12 MW, while heavy diesel-electric locomotives typically produce/consume 3 to 5 MW.

Watt Examples

- A person having a mass of 100 kilograms who climbs a 3 meter high ladder in 5 seconds is doing work at a rate of about 600 watts. Mass times acceleration due to gravity times height divided by the time it takes to lift the object to the given height gives the rate of doing work or power.

- A laborer over the course of an 8-hour day can sustain an average output of about 75 watts; higher power levels can be achieved for short intervals and by athletes.

- A medium-sized passenger automobile engine is rated at 50 to 150 kilowatts – while cruising it will typically yield half that amount.

- A typical household incandescent light bulb has a power rating of 25 to 100 watts; fluorescent lamps typically consume 5 to 30 watts to produce a similar amount of light.

- A typical coal power plant produces an output of 600–700 megawatts.

- A typical nuclear power plant produces an output of 900–1300 megawatts.

Key Term - Confusion of Watts, Watt-Hours, and Watts per Hour

The terms power and energy are frequently confused. Power is the rate at which energy is generated or consumed.

For example, when a light bulb with a power rating of 100W is turned on for one hour, the energy used is 100 watt-hours (W•h), 0.1 kilowatt-hour, or 360 kJ. This same amount of energy would light a 40-watt bulb for 2.5 hours, or a 50-watt bulb for 2 hours. A power station would be rated in multiples of watts, but its annual energy sales would be in multiples of watt-hours. A kilowatt-hour is the amount of energy equivalent to a steady power of 1 kilowatt running for 1 hour, or 3.6 MJ (1000 watts x 3600 seconds (i.e., 60 seconds/minute x 60 minutes/hour) = 3600000 Joules = 3.6 MJ).

Terms such as watts per hour are often misused. Watts per hour properly refers to the change of power per hour. Watts per hour (W/h) might be useful to characterize the ramp-up behavior of power plants. For example, a power plant that reaches a power output of 1 MW from 0 MW in 15 minutes has a ramp-up rate of 4 MW/h. Hydroelectric power plants have a very high ramp-up rate, which makes them particularly useful in peak load and emergency situations.

Major energy production or consumption is often expressed as terawatt-hours for a given period that is often a calendar year or financial year. One terawatt-hour is equal to a sustained power of approximately 114 megawatts for a period of one year.

The watt second is a unit of energy, equal to the joule. One kilowatt-hour is 3,600,000 watt-seconds. The watt-second is used, for example, to rate the energy storage of flash lamps used in photography, although the term joule is normally used rather than watt-second.

Part B - Quick Overview of Generator Function - Making Electricity

Generator operation is based on the principle of electromagnetic induction. This means that voltage is generated when any conductor is moved at right angles through a magnetic field. When voltage is produced in this manner, it will cause the current to flow in the conductor if that conductor is a complete circuit.

Key Terms (Below) - For Reference